Contracting Service

Under engineering contracting, we provide installation and commissioning services for the different disciplines such as Modular cleanroom, HVAC, Mechanical utility piping, Electrical low tension, plumbing, Firefighting, Laboratory and medical gas piping, etc. as a package or individually based on the client’s requirement.

There are three types of contracting services,

In this we provide our skilled technician and labor team to execute the installation work. The procurement of the item remains in the client's scope.

In this case, based on the client's/consultant's BOQ, specification, make list we purchase the material and do the installation work.

This case is referred as EPC solution in which engineering designing, procurement & construction will be done under one roof. This involves preparation of different drawings, BOQS, technical specification sheet, make list, procurement of all the line items, project planning, scheduling and supervision, installation, validation & commissioning.

The disciplines for which we offer EPC contracting service:

Modular Cleanroom Panel & Flooring

A modular cleanroom is a controlled environment constructed using prefabricated components, offering flexibility and ease of assembly. Equipped with HVAC systems, it controls temperature, humidity, and particle levels. Designed for industries like pharmaceuticals and electronics, it ensures compliance with cleanliness standards (ISO 14644-1). Its modular design allows easy expansion or relocation to adapt to changing requirements. Personnel wear specialized garments, and HEPA/ULPA filters maintain a contaminant-free atmosphere, making it vital for processes where even minimal particles can impact product quality.

- Wall panel and its accessories

- Ceiling panel and its accessories

- Corner profiles: Coving, Elbow, 1/4 corner, 1/8 corner, Door corner, etc.

- Cleanroom door & Emergency exit door

- Double glazed view panel

Heat Ventilation and Air Conditioning

A cleanroom HVAC (Heating, Ventilation, and Air Conditioning) system is a specialized setup designed for controlled environments with stringent cleanliness requirements. It employs high-efficiency filtration, typically HEPA or ULPA filters, to remove particles from the air. The system maintains precise control over temperature, humidity, and pressure to meet cleanroom standards (ISO 14644-1). Air is circulated and filtered to minimize contaminants, ensuring a sterile environment crucial for industries like pharmaceuticals, electronics, and biotechnology. The HVAC system in a cleanroom plays a pivotal role in sustaining optimal conditions for sensitive processes and ensuring compliance with regulatory standards.

- Capital equipment Low side: AHU, TFA, EXU, VRF, Condensing unit, etc

- Ducting & Insulation: GI ducting, Pre-insulated ducting, Pre-fabricated ducting

- Air supply unit: Terminal box (GI/Alu), HEPA /ULPA filters

- Air return unit: Riser grill, Fine filter, VCD

- Accessories: Air diffuser (4 way/Jet), VCD, Fire damper, Fusible link, etc.

- Instrumentation: T-RH sensor, Air velocity sensor, DPT, Magnehelic gauge, Smoke detector, etc.

Utility Piping

A mechanical utility piping system refers to a network of pipes designed for transporting various utilities within a facility, such as water, steam, compressed air, or gases. It includes components like pipes, valves, pumps, and control systems. The system ensures the reliable distribution of utilities to support industrial processes, heating, cooling, and other operational needs. Proper design and maintenance are crucial for efficiency, safety, and compliance with industry standards. Mechanical utility piping systems are integral in diverse sectors, including manufacturing, energy, and commercial buildings, contributing to overall infrastructure functionality.

- Capital equipment: Chiller, Air compressor, Hot water Generator, Cooling tower, steam boiler, etc.

- Distribution system: Transfer pump, Expansion tank, Air separator, safety valve

- Pipe (MOC: MS/CS/GI/SS) & fittings (Elbow, Tee, Reducer, Flanges, Gasket, Nut bolts, coupling, Nipple, Puff saddle, etc.)

- Valves (Ball, Butterfly, NRV, Balancing, Piston) & accessories (Bellow, Strainer, steam trap, air vent, etc.)

- Instrumentation: (Pressure gauge, temperature gauge, Flow transmitter)

- Insulation: (Nitrile rubber, Rockwool, GI/SS Cladding)

- Piping Support: Structural steel support, MS angles, Puff support, U bolt support, Clamps, Anchor fastener, etc.

Firefighting & Fire Hydrant System

Firefighting and fire hydrant system is a critical safety infrastructure designed to detect, control, and extinguish fires in buildings. Firefighting includes fire alarms, sprinklers, fire extinguishers, and smoke detectors. Automatic sprinkler systems release water or other extinguishing agents when triggered by heat, suppressing fires. Fire hydrant comprises water storage tanks, pumps, and a network of pipes connecting fire hydrants strategically placed throughout the facility. In case of a fire, firefighters connect hoses to hydrants, accessing pressurized water to extinguish flames. Regular inspections, testing, and maintenance ensure the system's effectiveness. Firefighting systems are vital for safeguarding lives and property, minimizing fire damage, and facilitating a prompt emergency response.

- Fire alarm system: Smoke & heat detector, response indicator, addressable sounder, manual call point,

- Fire hydrant system: Storage tank, Hydrant pump, Jockey pump, booster pump, hose pipe.

- Electrical system: Control panel, cables, cable tray

- Piping system: Pipes & fittings, Valves & accessories

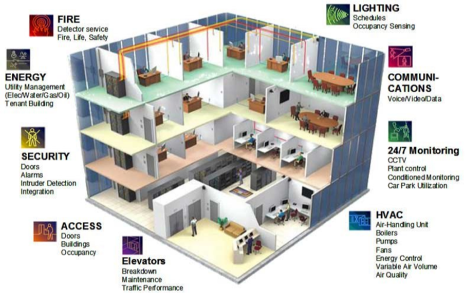

Plant Automation: EMS/BMS System

The Environmental Management System (EMS) and Building Management System (BMS) work in tandem to enhance sustainability and operational efficiency. EMS focuses on environmental impact, addressing energy consumption and waste reduction. BMS oversees building functions like HVAC, lighting, and security, ensuring optimal performance and occupant comfort. Integration allows comprehensive control, monitoring, and data analysis, enabling organizations to reduce resource use, minimize carbon footprint, and create environmentally responsible and comfortable spaces.

- BMS System: DDC Panel, BMS software, centralised computer, BMS server

- BMS Sensors: T-RH Sensor, DP transmitter, DP switch, smoke sensor

- EMS device: Temperature & RH Display, Differential Pressure Indicators, GPS clock.

- Electrical: Cables, PVC conduit, cable tray

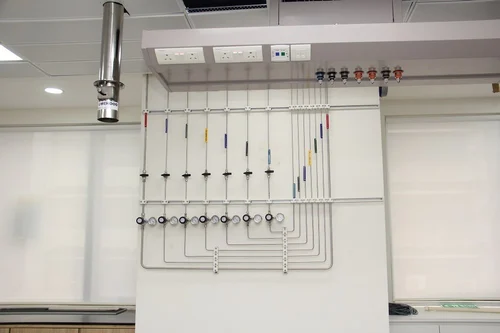

Lab Piping

Lab gas piping refers to a system designed for the safe distribution of gases within laboratory settings. This infrastructure includes pipes, fittings, and valves to transport various gases required for experiments and analyses. Materials like stainless steel or corrosion-resistant alloys are used to maintain gas purity. The system is carefully designed to prevent leaks, ensure precise control of gas flow, and adhere to safety standards. Lab gas piping plays a critical role in supporting scientific research by providing a reliable and controlled supply of gases essential for laboratory processes. Regular maintenance is crucial to uphold safety and operational integrity.

- Gas generators, Gas detection system, Gas distribution Panel, Gas monitoring system

- Gas purification & control system, Gas analyser, Automatic changeover system

- Distribution system: Pipes & fittings, tubes, manifold, regulators, valves, flexible hose

- Low gas alarm system: Panel, Gauge, Transmitter

Electrical Low Tension & Extra Low Voltage

Electrical Low Tension (LT) refers to the distribution of electrical power at voltages below 1,000 volts AC. It includes standard industrial and commercial power supply voltages. LT systems power lighting, appliances, and general electrical outlets. Extra Low Voltage (ELV) typically refers to voltages below 50 volts AC or 120 volts DC. ELV systems power telecommunications, data networks, security systems, and electronic devices. Both LT and ELV are critical for diverse applications, with LT serving higher-power needs and ELV ensuring safety for sensitive electronics and communication equipment. Proper design and installation are essential for efficiency and safety.

- Capital equipment: Transformer, Diesel generator, UPS, etc

- Panel: Main LT Panel, Distribution panel for Machine, AHU, DDC, etc.

- Distribution system: Armoured cables, flexible cables, termination end, cable tray & cover, cable tray support, PVC conduit, etc.

- Electrical Switch socket, LED lighting & fixtures, Industrial socket

- ELV: Access control, Door interlocks, CCTV camera, intercom, speaker, mic & amplifier.